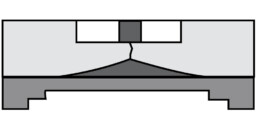

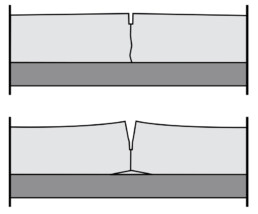

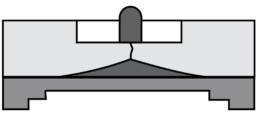

The improper or rushed curing of concrete slabs have a tendency to cause lifting near joints or along the perimeter of slabs, which can sometimes cause the slab to lose contact with the underlying fill material.

Proven Procedures

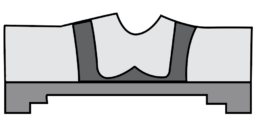

Dumoulin & Associates uses injection grouting to fill the void beneath the slab.

A necessary repair

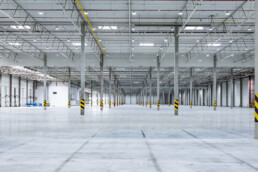

In industrial buildings, such as factories and warehouses, concrete floors must remain smooth and flat to allow for proper operations of material handling equipment. For a forklift, as little as rolling over a curling joint can make it scrape the floor and damage its wheels.

In a similar fashion, the edges of a slab can chip or crack if the foundation supporting it erodes.

Under these conditions, the floors can deteriorate rapidly, therefore causing security problems.

Don’t wait!

The main reason for curling

The curling of foundation slabs is mainly caused by differential shrinkage that happens when the exposed surface retracts with respect to the core, which doesn’t move.

This shrinkage is usually attributed to drying, but it can also be caused by carbonation of the concrete surface or, in the case of concrete rich in high strength cement, by internal drying (autogenous shrinkage) that happened during the hydration of the cement paste.

It is important to repair the slab that curled before it erodes the joints and causes more damage.

Steel treatment

It is necessary to apply a corrosion inhibitor to eliminate rust on the reinforcing steel. The minimum thickness of the coating must be respected as part of the concrete restoration plan because the reinforcing steel would need replacement if they are too corroded.

The application of sacrificial anodes can also be considered. This new technique requires installing anodes specifically developed to corrode before the reinforcing steel, thus protecting the concrete structure.

A reliable technique

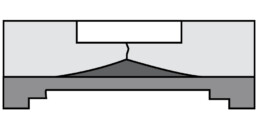

The local repair technique that we use consists of tackling voids beneath the slab with grout and then repairing the raised sections. To do this, we correct the perimeter of the raised area with a saw and remove concrete until the desired surface is obtained. We fill the consequently formed cavity and, finally, apply a flexible sealant to the crack or joint.

Injection grouting into voids

New cut and joint filling

Saw cutting and mortar filling

Result: smooth and levelled joint